Automotive Simulation Testing: Understanding MIL, SIL, and HIL for Smarter Vehicle Development

Simulations are taking over the world, and while they cannot beat real-world executions, they certainly cut down on quality testing costs. In fact, quality tests are extremely expensive since manufacturers must procure testing equipment, hire test personnel, and even risk their prototype breaking down in the first go.

Automotive simulation testing makes this much simpler by allowing you to instantly test your vehicle’s key parameters using virtual modelling. Here is how!

What is Automotive Simulation Testing?

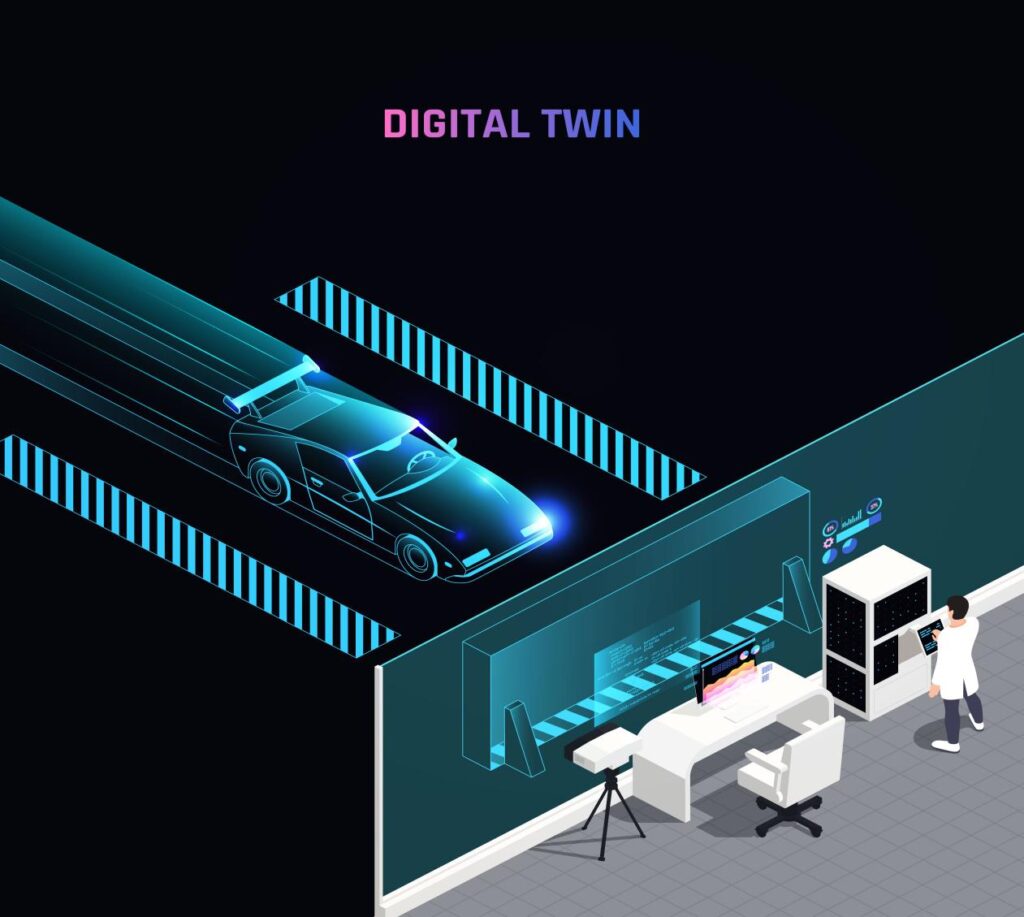

Automotive simulation testing is one of the most popular forms of automotive testing today, made possible through virtual AI models. It allows the manufacturer to evaluate a wide range of parameters, including vehicle efficiency, safety, performance, responsiveness and more.

The feedback received from a single test or even a series of tests can be used to improve the prototype before it is deployed for real-world testing. In a way, this form of testing helps reduce costs while simultaneously accelerating innovation.

Furthermore, simulation testing will allow you to test in more radical experiment settings, which may be difficult to recreate in real settings. This translates into improved safety and optimized performance. Ultimately, quality automotive testing is vital for modern vehicle development.

Applications

The need for a robust and, more importantly, varied testing system is even more important as the automotive industry evolves. Software-defined vehicles are a prime example where the interface between software and hardware must be tested.

Vehicles being fitted with autonomous driving technology must be tested to see how they can realize specific functions under less-than-ideal circumstances. In the same way, the increasingly popular electric vehicles (EVs) and hybrid vehicles also demand testing for battery performance, charge efficiency, motors, inverters, axle modules, and similar parameters. For example, a vehicle might be tested to see how its battery might perform in cooler climates compared to warmer climates.

Understanding MIL, SIL, and HIL in Vehicle Development

Simulation testing for automobiles is achieved using any of the three testing environments. Before testing, the test object is identified, which can be the entire vehicle unit or a small part, such as the battery, bumper efficiency, or vehicle aerodynamics. Once the object is identified, it is placed in a virtual setting where it can interact with the environment.

Model-in-the-Loop (MIL)

In the MIL testing type, a model is tested within a simulated setting, allowing manufacturers to test its viability. The reason why MIL simulation testing is so popular is because it can be accomplished even prior to the production of actual hardware. So, you can test your vehicle in the earlier development stages and tweak the model as you go.

Software-in-the-Loop (SIL)

Software in the Loop or SIL test is different from MIL testing. SIL involves testing the code generated from the model and places more emphasis on the software than the model. For example, imagine a car engine being tested for how it reacts under different gear shifts; here, the underlying model and the controlling algorithm are being tested. SIL testing in automotive, on the other hand, would focus on the generated code to see if it behaves as expected.

Hardware-in-the-Loop (HIL)

Hardware in the Loop testing, or HIL testing, is a form of simulation testing within which a part of the hardware is being tested by joining it with the virtual system. By isolating a single unit, the manufacturer can better assess the component by removing other variables. For example, an EV electrical battery may be tested to assess how it may recharge and perform under rapid temperature changes.

Learn More at Mobility Tech Asia 2025

Mobility Tech Asia 2025 is one of the best events for any automotive enthusiast or industry competitor who wishes to learn more about groundbreaking technologies, including how vehicles are tested through simulation testing.

Besides, here are more you can learn:

- Charging Pile & Battery Swapping Equipments

- New Energy Transformation Components & Solutions

- Hydrogen & Fuel Cell Technology

- Software & Tool Chain

- New Energy Mobility Key Technologies and OEM/ODM

Mobility Tech Asia will bring together over 350 mobility technology manufacturers and 150 speakers from around the globe; do not hesitate to join us for more mobility trends and technologies!